In the demanding environments of international logistics, labels are essential data vehicles. A discrepancy in color management isn't just an aesthetic issue—it is a potential breakdown of the entire supply chain infrastructure.

At Coding Solutions (CSI), we approach these "chromatic failures" through the lens of material science and mechanical engineering. Achieving a brand-accurate mark requires the perfect synchronization of digital color theory, chemistry, and hardware calibration.

Color shifts are typically caused by a mismatch between the digital source's surface energy and the printer's delivery method.

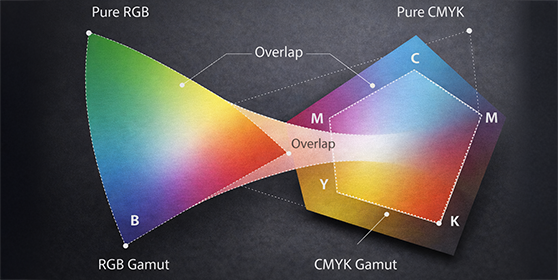

The most persistent "mystery" failures occur when designs created on 4K monitors (RGB) meet industrial presses (CMYK).

To bridge the gap, use high-LAC media like White BOPP to prevent "bleeding" and ensure vibrant subtractive color reproduction.

Industrial systems like the Zebra ZT series require high-contrast ribbons to maintain barcode decodability despite chromatic shifts.

Achieving brand accuracy means managing the Pantone Matching System (PMS) within the constraints of CMYK. This requires hardware that can hit specific "out-of-gamut" colors through high-density pigment delivery.

Without proper calibration, aesthetic choices can lead to a lack of barcode contrast, resulting in electronic unreadability at the scanner.

At Coding Solutions, we don't just sell labels; we engineer uptime. Our technical team is here to ensure your color management strategy results in flawless execution.